- #Cnc simulator lathe how to#

- #Cnc simulator lathe 64 Bit#

- #Cnc simulator lathe manual#

- #Cnc simulator lathe software#

- #Cnc simulator lathe download#

The software works offline, which means you don’t have to be connected to the internet to run the software. If you have a multi-processor CPU it can help the software with multi-threaded rendering.

#Cnc simulator lathe 64 Bit#

It’s compatible with 32 and 64 bit Windows, Mac, and Linux-based operating systems.

#Cnc simulator lathe download#

We also supply PLC trainer kits for educational purpose.CAMotics is an open-source software, which is freely available for anyone to download and use.ĭon’t get confused by its name, it can’t perform CAM operations as of now, for that you will need additional CAM software. We have more than 400 Trainers working efficiently in top educational institutes all over India. We are also leading manufacturers of Hydraulic – Pneumatic Trainers. We have collaboration with Cut Viewer (UK) for software support and ALSTRON (Singapore) for technical support. In the current era, when China is considered as the best manufacturing hub in the world, we are proud to have supplied our INDEGENIOUS CNC TRAINERS to 5 Educational Institutes in China. Intelligent investment in CAD-CAM laboratory will help students to build their own skill set and confidence. You can train your lab assistants at our Pune Training Centre at FREE OF COST.ĬNC TRAINERS AND HYDRAULIC – PNEUMATIC TRAINERSĮducational Institutes in India are playing a major role in developing potential young generation.

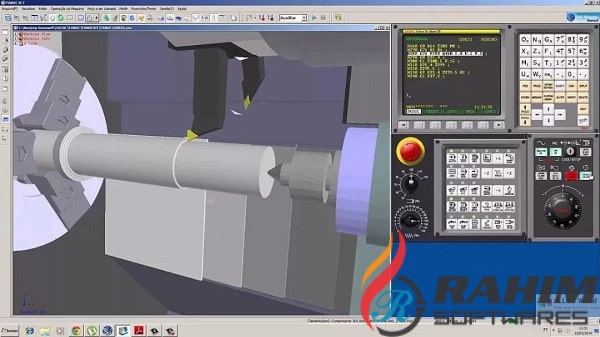

We are proud to have opened our CNC Training Center for lab assistants. Our Robots are based on PLC technology which can be directly interfaced with our machines. ‘Hytech’ is also a reputed manufacturer of Robotic Arms required for Robotic / Automation Lab. We also offer total solution to CAD-CAM lab with Latest CAM Software and AMC Contracts. ‘HYTECH’ offers all types of CNC Machines such as Trainers, Semi-Production Machines and Production Machines with FANUC / SIEMENS / MITSUBISHI controller. ‘HYTECH’ follows the tradition of latest technology & provides strong service support. CAM programs generated from MasterCAM and BobCAD can be executed on Hytech CNC Trainer machines. We have also established collaboration with MasterCAM (Onward Technologies) and BobCAD USA. Our machines can be directly converted into FMS (Visit our website to see FMS / CNC Lathe / Mill Videos). We have successfully developed and manufactured indigenous ‘Flexible Manufacturing System’ based on PLC technology. Servo motors from Siemens / Mitsubishi can achieve the resolution of 1 micron and Rapid feed rate of 10,000 mm/min. Our CNC Trainer machines are equipped with Servo Motor technology which is much more advanced than stepper motor based technology generally used in CNC trainer machines. Till date, we have established 9 CNC Skill development centers for Govt. We are proud to announce that we are now authorized manufacturers and suppliers of CNC machines to ‘SKILL DEVELOPMENT PROJECT’ OF GOVT. More than 30,000 students all over India are trained on Hytech Trainers per year. We have supplied 950+ INDEGENIOUS CNC TRAINERS to more than 600 Educational Institutes all over India. ‘HYTECH’ is the name associated with CNC Trainers for the past 23 years. Place this program in the root folder of a USB memory stick now to be ready for the upcoming program-manipulation procedures.ĬNC TRAINERS, ROBO & LAB EQUIPMENT FROM HYTECHĬUTVIEWER (United Kingdom) & ALSTRON (Singapore) The program is named Program.nc, and can be downloaded from. Example program must be downloaded During this quick tour, you will load, run, graph, and delete a practice program. Again, be sure the machining center configuration is selected before continuing with this quick tour.

#Cnc simulator lathe manual#

Hold CTRL-T until you see the message that Manual Guidei is loading Data (programs and offsets, for instance) will be saved while using one configuration or the other, even after power off, but data will be lost when you switch machine configurations. Turning center (lathe) To select the turning center configuration, hold the CTRL and T keys while press the ON button. Hold CTRL-M until you see the message that Manual Guidei is loading. To select the machining center configuration, hold the CTRL and M keys while press the ON button. Two machine types are supported Machining center (mill) this configuration is used for the quick tour. After introducing you to its main components, we will provide you with several hands-on procedures aimed at getting you familiar with several common CNC tasks. If you can perform a task with the FANUC Simulator, you will then be able to perform the task on an actual FANUC CNC that is connected to a CNC machine.

#Cnc simulator lathe how to#

The FANUC Simulator provides a save environment for which to learn how to operate a FANUC CNC.

0 kommentar(er)

0 kommentar(er)